Description

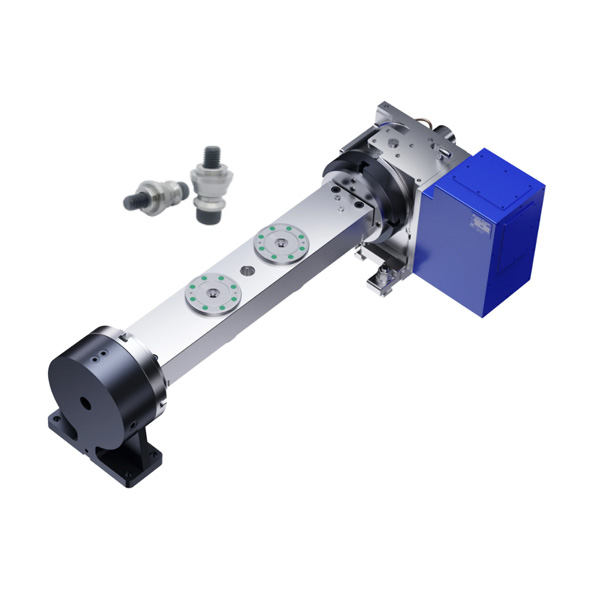

Four-Axis Dual-Sided Zero-Point Positioning Bridge Board, this board features two sides, A and B, allowing simultaneous installation of two interchangeable tooling plates. It enables you to perform various machining processes on a single device, providing you with a more efficient and convenient solution for your CNC operations.

To ensure precise positioning, each side of the zero-point positioning bridge board is equipped with a pneumatic switch, allowing you to control the positioning of each side separately. This enables you to quickly and accurately switch between working surfaces, thereby enhancing production efficiency.

The four-axis tailstock is equipped with a rotating air connector to address the issue of air hose entanglement during four-axis machining. This design allows for a neater arrangement of air hoses, reduces operational obstacles, and ensures smooth machining processes.

Up to 90% less set-up time

Increase of machine running time

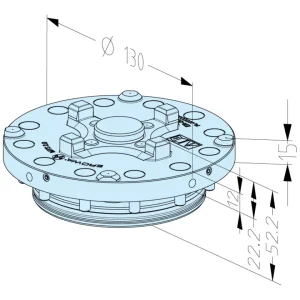

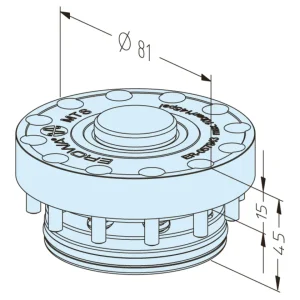

High repetition accuracy 0.005mm

Positioning and clamping in one operation

Single zero-point body has high holding force up to 55 kN, high pull-in and locking force up to 17 kN

List of items:

K20.3-C4-F2*1

air intake switch*2

Rotary air connection*1

matching rivets (A/B)*4

Four-axis L block*2

Positioning axis*2