Description

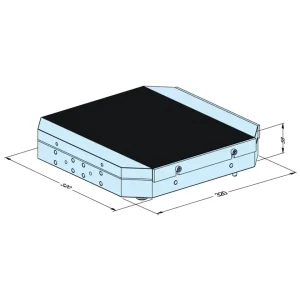

The zero-point positioning pallet is not limited to the processing of a single product. We can design different interchangeable fixture plates according to different product specifications. When we need to process different products, we only need to replace the corresponding interchangeable fixture plate. The zero-point positioning pallet provides precise zero reference points, allowing us to align the workpiece accurately with the pallet and ensure the accuracy of the zero reference points.

Similarly, in CNC programming, the position and clamping method of the zero-point positioning pallet and fixture are fixed. Therefore, we reduce the time required for manual measurement and determination of fixture positions. We can directly integrate the fixture with the programming process, reducing the setup time for fixtures. This workflow improves workshop productivity and promotes standardized, modular, and standardized production in the workshop.

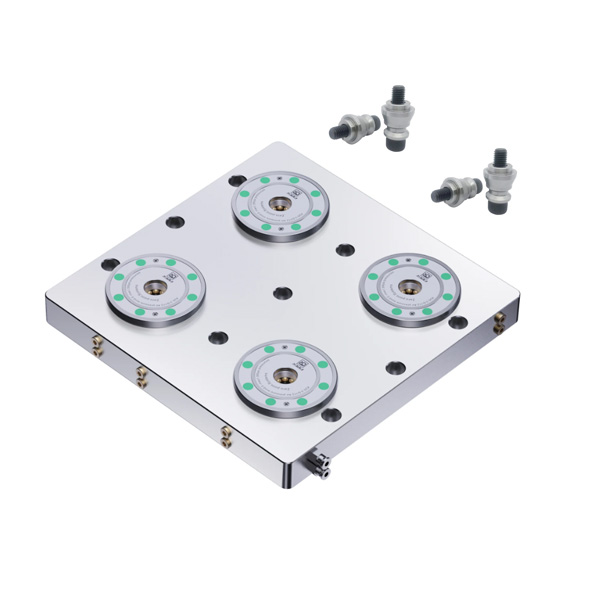

List of items:

K20.3-C4*1

air intake switch*1

matching rivets (B/B/B/B )*2

installation accessories (screws, T-block, dust cover, rivet cover)